Over recent years, the boom of mining has seen many school leavers and other young people seek out a mining career, thanks largely to its high wages. Retraining by slightly older workers has also added to the pool of...

According to a new research report from IoT market research provider Berg Insight, the total active installed base of connected mining solutions reached close to 1.3 million units in the equipment, people and environment segments in 2023. Growing at...

Gaining a strong reputation in the industry, MAXAM Mining Group continues to innovate, adding the all-new MS412 27.00R49 to their open pit mining, quarry and OTR program.

Designed to meet the demanding conditions in mine sites globally, the MS412 is...

In this regular column, Jenike & Johanson’s general manager, Grant Wellwood, discusses how asymmetric loading can cause serious productivity losses.

Q. Our plant has recently installed dynamic optimisation software which monitors our entire value chain, generating insights to maximise...

Caterpillar announced a collaboration with Luck Stone, the nation's largest family-owned and operated producer of crushed stone, sand, and gravel, to deploy Caterpillar's autonomous solution to Luck Stone's Bull Run Plant in Chantilly, Virginia. This will be Caterpillar's first...

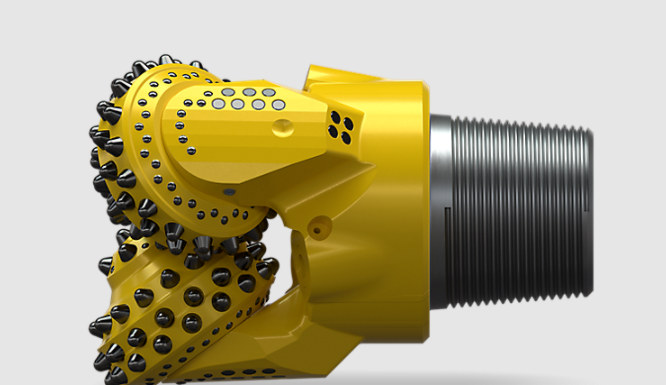

Epiroc is now launching Omega S - the new tricone rotary drilling bit.

A single sealed bearing bit that, when the seal eventually wears off, transforms to an air bearing bit thus increasing drilling performance with up to 30 percent...

With a whole new chassis, powertrain and operator cabin, Komatsu’s brand-new WX07 7-tonne LHD has been designed from the ground up to provide a standout experience and environment for underground hard rock mining operators.

Compared to competitors in its size...

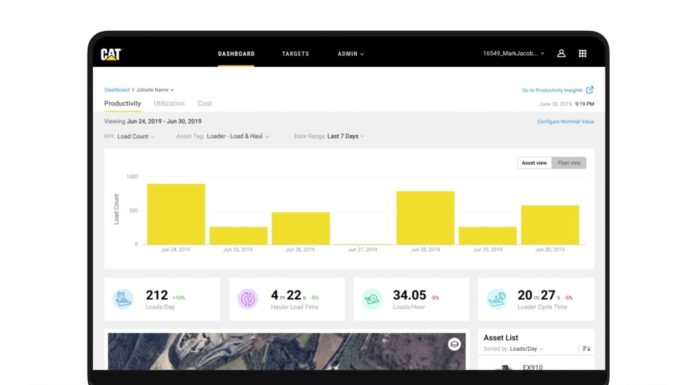

Cat Productivity is easy to implement a cloud-based application that provides a complete overview of the machine and job site production. It is a data-rich tool that delivers consolidated and actionable site-level information to analyze performance, improve productivity and...

The Aussie experts in all things roof storage and beyond, Rhino-Rack, are proud to present their comprehensive guide to the ultimate tradie rig—for the on-site professional who cares not only about performance, but durability in the face of long...

Liebherr presents the latest editions and upgrades for its mining product range at MINExpo International 2021. Including equipment from its hydraulic excavator, haul truck, dozer, components, and rough terrain mobile crane product lines, the OEM’s product developments have been...

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.