Continental used this year’s ConExpo/ConAgg to show how it is set to support the upcoming productivity leap in the construction and mining industries triggered by digitalization. At ConExpo/ConAgg the company showed how it interprets its role as an innovation partner under the motto “We build tomorrow. Now.”

“The construction industry is about to undergo a profound transformation in the coming years. Productivity per construction machine is set to significantly rise thanks to digitalization, creating more value throughout the construction industry. Continental is ideally positioned to support the industry as a reliable innovation partner. As an automotive supplier and technology company, Continental has set itself the ambitious goal to help shape tomorrow’s construction and mining industry today. Thanks to our broad expertise in the fields of digitalization, automation, connectivity, material competence and sustainability we are extremely well positioned to realize this technological leap together with the industry,”

says Mario Branco, Head of Business Development Off-Highway at Continental.

Adapting what works for passenger cars, trucks or buses

Continental is achieving further innovations by using passenger car technology and adapting it for construction and mining machinery. For the digital surround view system ProViu 360, the technology company will present several software-based features. Worker Detection, for example, allows the system to detect people near a machine and warn them of collisions. For the ProViu 360 system a platform approach ensures that customers can easily upgrade with new functions without having to make changes to hardware or install new software.

Another benefit of the platform approach is that sensors other than cameras, like radar, will be added to ProViu 360 in the future, taking the next step toward automating construction machinery. Another innovation based on a Continental solution for road traffic is the Digital Safety Assistant. In the version of this system for construction sites, people, machines and vehicles communicate with one another via signals that they send through a smartphone or telematics unit. In this way, every machine and every person can be warned in real time of an impending collision.

Continental relies on its success with commercial vehicle manufacturers where several projects have already been awarded, for example with 5G-Hybrid-V2X solutions. Also, as the technology company is used to looking at least one technological generation ahead, 6G development has started at the labs of the company’s Software and Central Technologies unit.

Ismail Dagli, head of the Automotive Business Area Smart Mobility, wraps it up:

“We are sure that the construction and mining industries will benefit strongly from automotive technology in the years to come, and that the industries are only just beginning to see how big this potential is.”

Building asset management and IoT solutions to reap an enormous productivity potential

Tire data, such as air pressure and temperature, is recorded and evaluated with the help of the digital tire management system ContiConnect 2.0. If the tire pressure is too low or there is a risk of overheating, the driver is informed directly via a warning system. This ensures a fail-safe, long tire life and fuel-efficient operation. At Continental, all radial tires for earthmoving are equipped with a sensor ex-factory, making them ready for use with ContiConnect.

The revised app-based service platform Conti+2.0 integrates numerous conveyor monitoring systems and processes in a single application and analyzes all important sensor data. This helps companies improve the productivity of their operations and extend the life of their conveyor belts.

![]()

With its new IoT solution Zonar SightIQ (IoT = Internet of Things), Continental is setting new standards for productivity management in quarries, mines and on construction sites.

SightIQ integrates all available data from mobile machines, vehicles and stationary equipment such as conveyors or tools in a cloud application, regardless of the manufacturer. SightIQ Predict collects and decodes proprietary ECM data across major manufacturers and translates that data into actionable insights and predictive diagnostics, inspection, and peripheral data. SightIQ Optimize consolidates site data into real-time information, regardless of location, across entire fleets. It grants select personnel access to the data so they can streamline site processes and enhance location efficiencies.

Sustainability is the standard of the future – environmentally and commercially

“We are convinced that sustainable and responsible business practices will increase our innovative capacity and future viability and are essential for Continental’s future success. For this reason, we are actively researching products and solutions for a carbon-free future,”

explains Song Qi, head of the Conveying Solutions business area.

The electrification of off-highway machines increases efficiency as well as productivity and can help to limit emissions. With its holistic approach, Continental offers a comprehensive portfolio of hardware and software for electric machinery with architecture and consulting, software or product development. Products like power electronics, low voltage electronic control units, powertrain auxiliaries or sensors were displayed at ConExpo.

Continental has developed two green, efficiency-boosting tire concepts that are making an immediate impact on sustainability efforts: the Conti Urban Green concept tire and ContiTread EcoPlus Green concept retread.

When designing the newest version of the Conti Urban Green concept tire, Continental tire developers focused their efforts on achieving high energy efficiency and reduced noise. A special rubber compound in the tread, a wider tire tread, and a specially optimized and exceptionally rigid profile help increase tire life and reduce rolling resistance by seven percent compared with a current-generation Conti Urban. These new gains have been achieved without compromising on the tire’s safety performance properties.

ContiConnect digital tire monitoring provides fleet managers with real-time data such as tire pressure, temperature and mileage estimation so they can keep their tires running at optimal performance levels. This improves fuel efficiency, reduces maintenance and replacement costs, and maintains operator safety. The modular format of ContiConnect allows it to be tailored to meet each individual customer’s needs.

While retreading worn out tires is a sustainable practice in its own right, the ContiTread EcoPlus Green concept retread takes it a step further. Thanks to the high content of renewable materials used in the tread, retreading with the ContiTread EcoPlus Green concept increases the overall share of sustainable materials in the tire to 90 percent. A special rubber compound, along with wider tread, and exceptionally rigid profile provide considerable reductions in rolling resistance and optimize noise emissions.

Material competence enables better productivity and lower TCO

In 2022, Continental acquired family-owned belting manufacturer WCCO Belting headquartered in Wahpeton, North Dakota. At ConExpo 2023, Continental for the first time presented a product innovation that shows what great material competency has been added to the technology companies’ knowledge base. The patented Direct X conveyor belt technology for crushing, grinding, sorting, screening and piling operations in the aggregate and recycling industries is now available for purchase by original equipment manufacturers (OEMs) and the aftermarket. The patented Direct X cleat profile increases conveyor capacity by capturing more material across the belt width than standard industry patterns. Combined with the benefits of a specialized belt construction that is thinner, yet stronger and more flexible in design, the product is a high-value solution that reduces cover wear, increases energy savings, and improves belt life.

For the first time on display in North America is Continental’s ConveyorInspect drone-based service. An infrared and RGB camera-equipped drone inspects both sides of the conveyor following a pre-programmed flight routine. With the Drone Pilot inspection service, a certified pilot controls the drone and collects data in dangerous or hard-to-reach places. Visual data is uploaded to the cloud via the ConveyorInspect portal, and the data is then processed and analyzed by an artificial intelligence-based data pipeline, customized to detect conveyor component damage.

This service is only one element in Continental’s comprehensive range of monitoring systems and services that enable predictive maintenance and thus reduce downtime. Their holistic approach to Smart Conveyor Management has been recognized by this year’s jury of industry leaders and has been chosen as a finalist for the inaugural Next Level Awards Program through ConExpo/ConAgg. The ConExpo/ConAgg Next Level Awards celebrate exhibiting companies that are pushing the boundaries and developing next-level products, technologies and services designed to advance the construction industry.

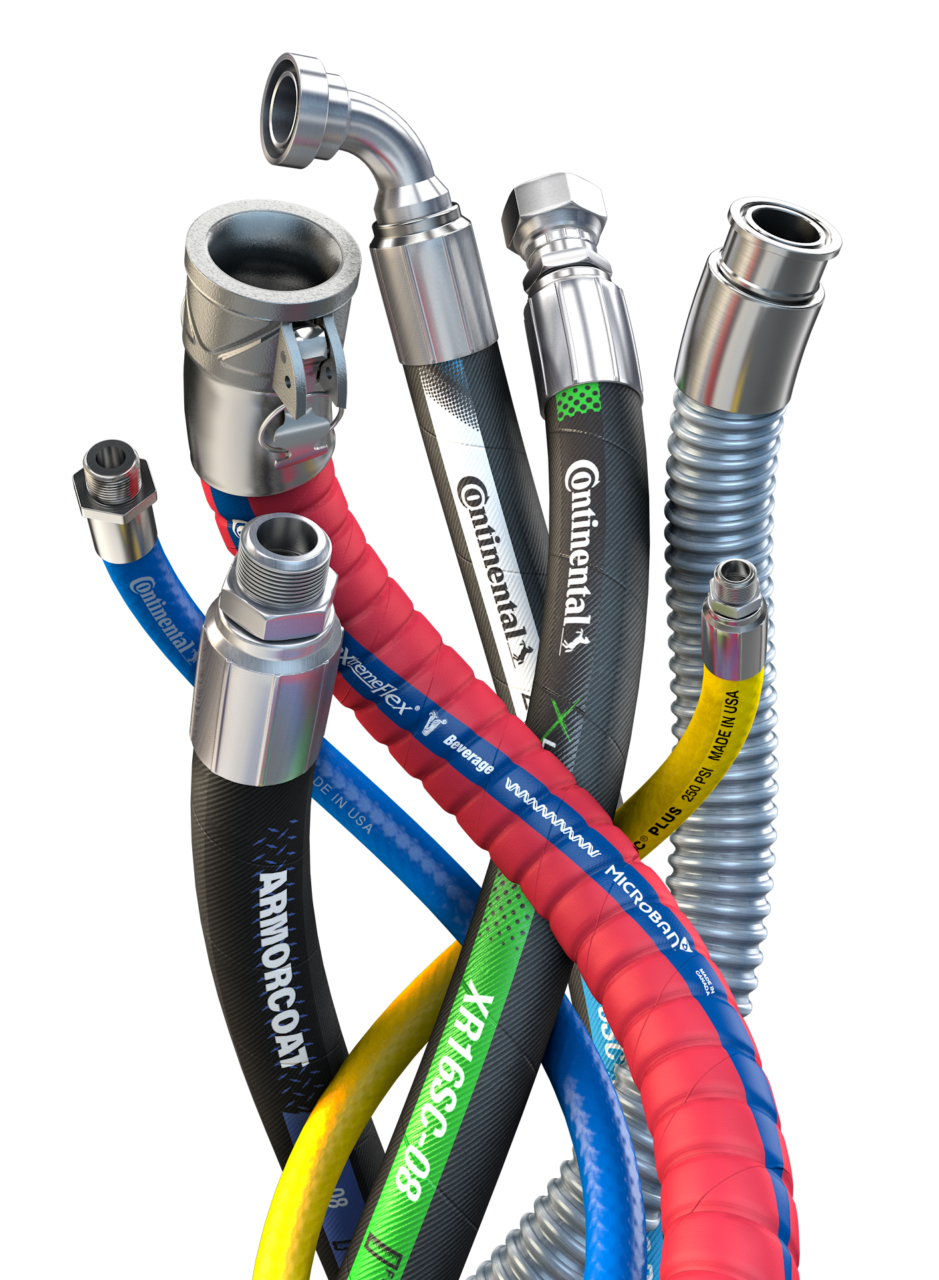

Also designed with the aim to reduce downtime are Continental’s top-selling hoses of the Gorilla series. The tube is made from carboxylated nitrile and provides superior oil and abrasion resistance. Gorilla hoses can soon be used in diesel applications, too. The hose experts of Continental’s Industrial Fluid Solutions business area are available at Continental’s second ConExpo booth at the International Fluid Power Exhibition (Booth S82411) to explain how they made this adaptation happen.

Continental’s new SAM (Shock Absorbing Mount) is the airless solution for spring replacement, vibration isolation and shock impact. Its innovative design will cut costs in most industrial applications as it is maintenance-free and thus reduces downtime. Its rubber and fabric compound are designed to handle damp and corrosive environments. SAM also dramatically reduces the noise level and can therefore help to improve working conditions.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.