Cummins reaffirms the company’s commitment to reach net-zero emissions from its products and business as part of its Destination Zero initiative and recent launch of Accelera by Cummins, a new brand representing a quickening pace of bringing zero-emissions solutions to market.

“Our strategy is to focus on the complete hydrogen value chain to drive sustainability and enable faster adoption,”

said Antonio Leitao, Cummins VP Off-Highway Engine Business.

This complementary approach lowers emissions today by matching technology readiness with infrastructure readiness to drive wide-scale adoption using the right technology at the right time.

“Our aim is to support our customers on their path to zero carbon emissions. This means meeting them wherever they are on their journey. We are leading the energy transition by providing our customers with the right technology and utilizing our deep understanding of their needs and applications,”

said Eric Neal, Executive Director of Cummins Off-Highway business.

On display, Cummins’ next-generation advanced 15-liter diesel platform showcases a practical route to emissions reduction and decarbonization for off-highway applications. It sits as part of the fuel agnostic product display, showing a common architecture optimized for a variety of low and no-carbon fuels including biodiesel and HVO, renewable natural gas, and hydrogen.

“We understand that no single solution or path to zero will work for all power needs, which is why we are developing the broadest combination of zero emission technologies: fuel cells, battery systems and fuel storage technologies,”

said Amy Davis, President of Accelera.

On display is the latest NMC battery, the BP95E, which has a long life and fast charging times, is suitable for compact equipment, particularly those that work in urban environments. Its modular design means it can be scaled to fit a number of installations based on the changing energy and packaging requirements.

Also on view is the next generation fuel cell engine, suited to the duty cycle, performance, and packaging requirements of heavy-duty off-highway applications. Available in 150kW and 300kW fuel cell engine configurations, it incorporates variable pressure technology, which provides improved power density, efficiency, and durability, all while delivering lower total cost of ownership.

As a result of Cummins’ acquisition of Meritor last year, Accelera’s product portfolio was broadened to include complementary ePowertrain products and EV powertrain integration capabilities. The Electric Central Drive Unit (eCDU) is a remote-mount electric powertrain designed for space limited off-highway applications. Its innovative architecture enables increased vehicle design flexibility with the ability to be located as needed. It helps reduce investment in vehicle architecture changes such as hydraulic brakes and driveline parking brakes.

As a result of acquisitions and investment, Cummins is focusing on three key areas for hydrogen: the production of green hydrogen, the management and transportation of hydrogen, and the application of hydrogen in engines and fuel cells.

Green hydrogen production

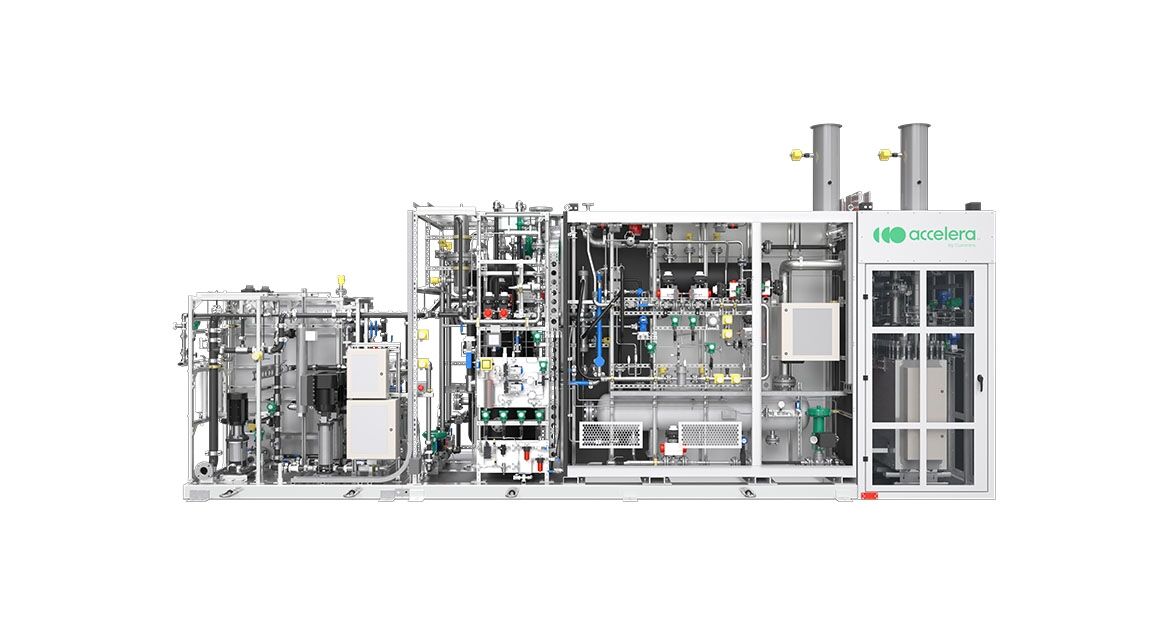

Green hydrogen is produced using electrolysis to turn sustainable power (wind, solar, hydro) into hydrogen with zero carbon dioxide emissions. The key tool to do this is an electrolyzer. Accelera is establishing new electrolyzer plants in La Mancha, Spain and Minnesota, USA as well as expanding production at Oevel, Belgium and Mississauga, Canada. On display is Accelera’s 1500E stack which forms part of a 2.5 MW PEM Electrolyzer.

Hydrogen storage and supply

On-board storage is a critical component of hydrogen power. Hydrogen needs to be compressed into the available space to store enough to meet vehicle duty cycle requirements. Cummins has a joint venture with NPROXX, a high pressure hydrogen storage for both stationary and mobile applications, to support the OEM integration process. Storage tanks will have a 700-bar pressure capability to maximize capacity and operating range.

Hydrogen engines

Cummins is developing hydrogen powered combustion engines which will provide sustainable solutions that are more aligned with current vehicle designs to reduce complexity for OEMs and their customers. The reuse of appropriate components drives economies of scale while also providing reliability and durability equal to diesel.

Visitors to Con Expo were able to see Cummins’ M15H hydrogen engine aimed at excavators, wheel loaders, drilling rigs, road planning, milling machines and air compressors, with a top rating of 530 hp (395 kW) and an impressive peak torque of 2600 Nm.

Hydrogen fuel cells

Hydrogen fuel cell technology can offer an efficient power solution for heavy-duty vehicles with high utilization and energy demands, while meeting zero-emission needs. The fuel cell uses oxygen to create a reaction, turning the hydrogen into electricity. It works alongside battery technology – ultra-capacitors, lithium-ion, or lead-acid – in a parallel hybrid set-up to deliver instantaneous response.

Accelera displayed its fourth-generation fuel cell engine at Con Expo which provides improved power density, efficiency and durability while delivering zero greenhouse gas and zero criteria air emissions. It is available in single 150 kW and dual 300 kW module engines for heavy-duty off-highway applications.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.