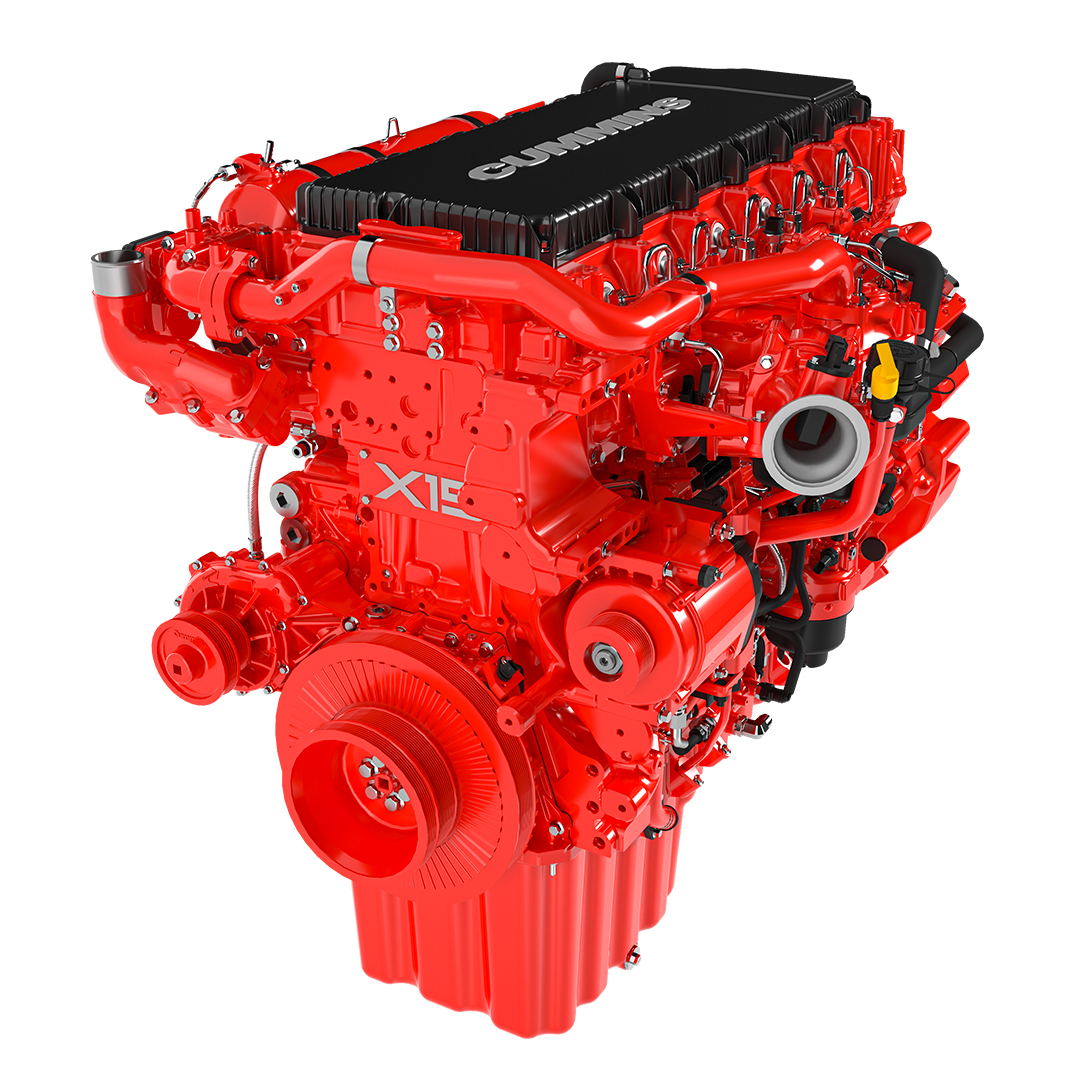

Cummins is launching the next product in the Cummins HELM 15-liter fuel-agnostic platform, the diesel X15, which will be compliant with U.S. EPA and CARB 2027 aligned regulations at launch. The next-gen X15 diesel engine in North America will serve the heavy-duty on-highway market.

“We have applied our decades of experience with the X15 to our next-generation product and believe these investments will serve our customers well into the future. The next generation X15 is the next evolution of technology, truly proving to the world that we never stop innovating. We are working hard to ensure the new product delivers our brand promise to customers for the important jobs they need to do every day.”

said José Samperio, Vice President, North America On-Highway at Cummins.

Maintaining the traditional reliability and lower operating costs that have met the needs of a diverse customer base since the inaugural X15 launch in 1998, the next generation, advanced diesel X15 will feature improved greenhouse gas and fuel efficiency benefits while retaining the same ratings of the current X15 (up to 605 horsepower and 2,050 ft-lb of torque) and optimizing powertrain integration with Eaton Cummins and Cummins-Meritor.

“Today, we re-introduce our fuel agnostic engine platforms with a name that captures the innovation that powers us forward: the Cummins HELM platforms. With higher efficiency, lower emissions, and multiple fuels, the Cummins HELM platforms give our customers control of how they navigate their own journeys as part of the energy transition. They can choose the fuel types that work best for them, their businesses, and their goals.”

said Jane Beaman, Vice President Global, On-Highway Business, Cummins.

This next-generation engine is designed to have the capability to meet future emissions regulations beyond 2027 without the need for significant architectural changes.

“This new architecture expands on the legacy of the X15 engine. All teams involved recognize how important this product is and what it means for both Cummins and our customers’ future as the base architecture will carry us through the horizon of diesel technology and alternate fuels.”

said Jonathon White, Vice President, Engine Business Engineering, Cummins.

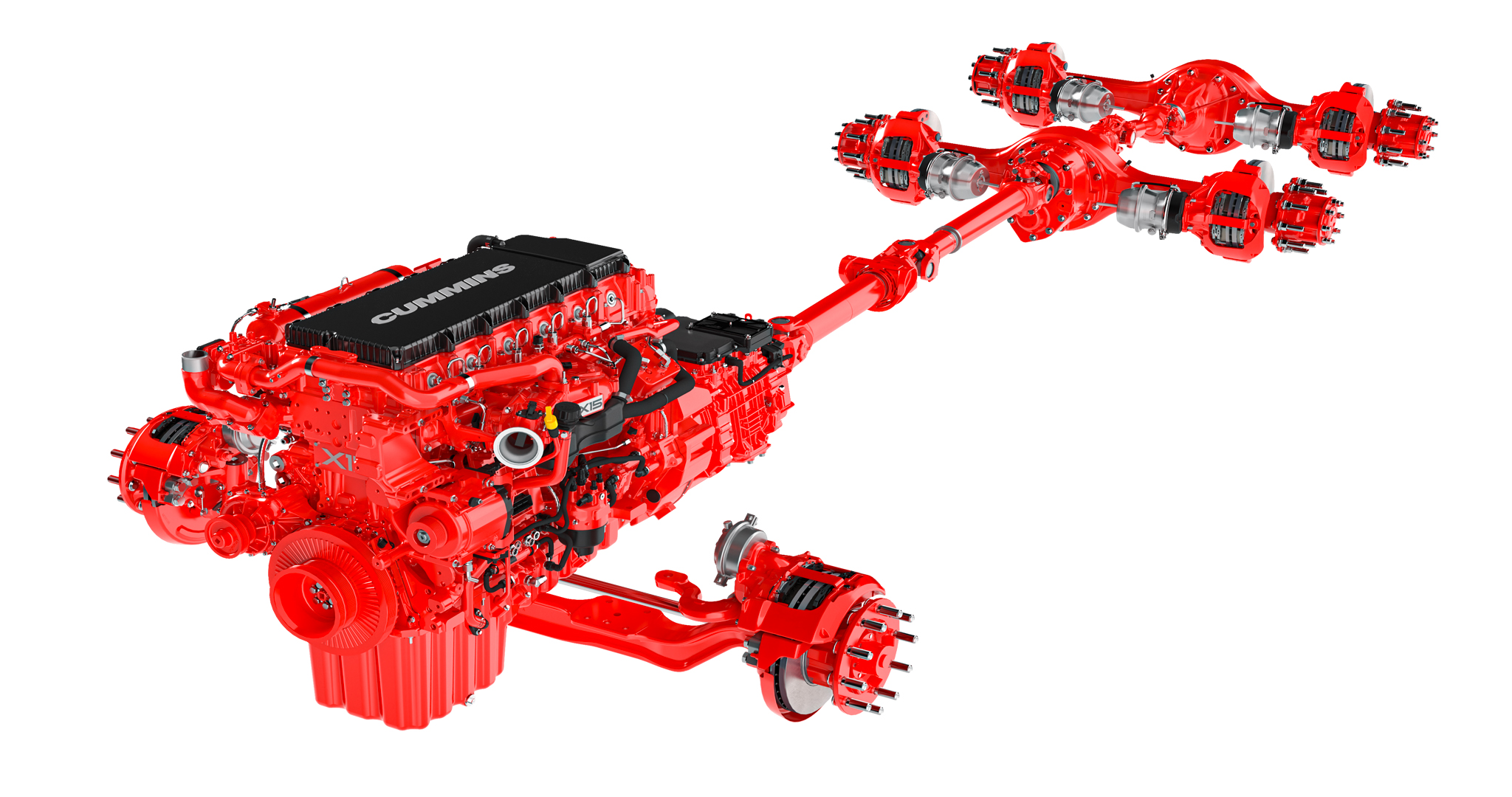

From its inception, the next generation X15 was developed with Cummins’ fully integrated powertrain in mind. The X15 architecture utilizes a belt-driven, high-output 48-volt alternator and aftertreatment heater solution, optimized for increasingly stringent emission standards.

Customers taking advantage of EX ratings (requires Eaton Cummins Endurant and GPS look-ahead data) with Cummins Meritor axles, brakes and drivelines will experience additional optimized fuel efficiency and drivability through features such as predictive gear shifting, on-ramp boost, and hill roll out.

Eaton Cummins Endurant

The Endurant HD and XD series are optimized for the next-generation X15 powertrain to work seamlessly, improving efficiency and performance while maintaining drive comfort. All with a best-in-class transmission lube change intervals up to 750,000 miles as well as remote diagnostic capabilities.

Cummins-Meritor Drivetrain Systems

The Cummins-Meritor 14X HE tandem drive axles are designed for maximum performance, durability and fuel economy. They are equipped with a proprietary, advanced Meritor lube management system (MLMS) and feature super-fast ratio options, fuel-efficient bearings and high-efficiency spiral bevel gearing. Cummins-Meritor Permalube RPL drivelines are designed for reduced maintenance and can handle the high torque demands of today’s downsped engine platforms.

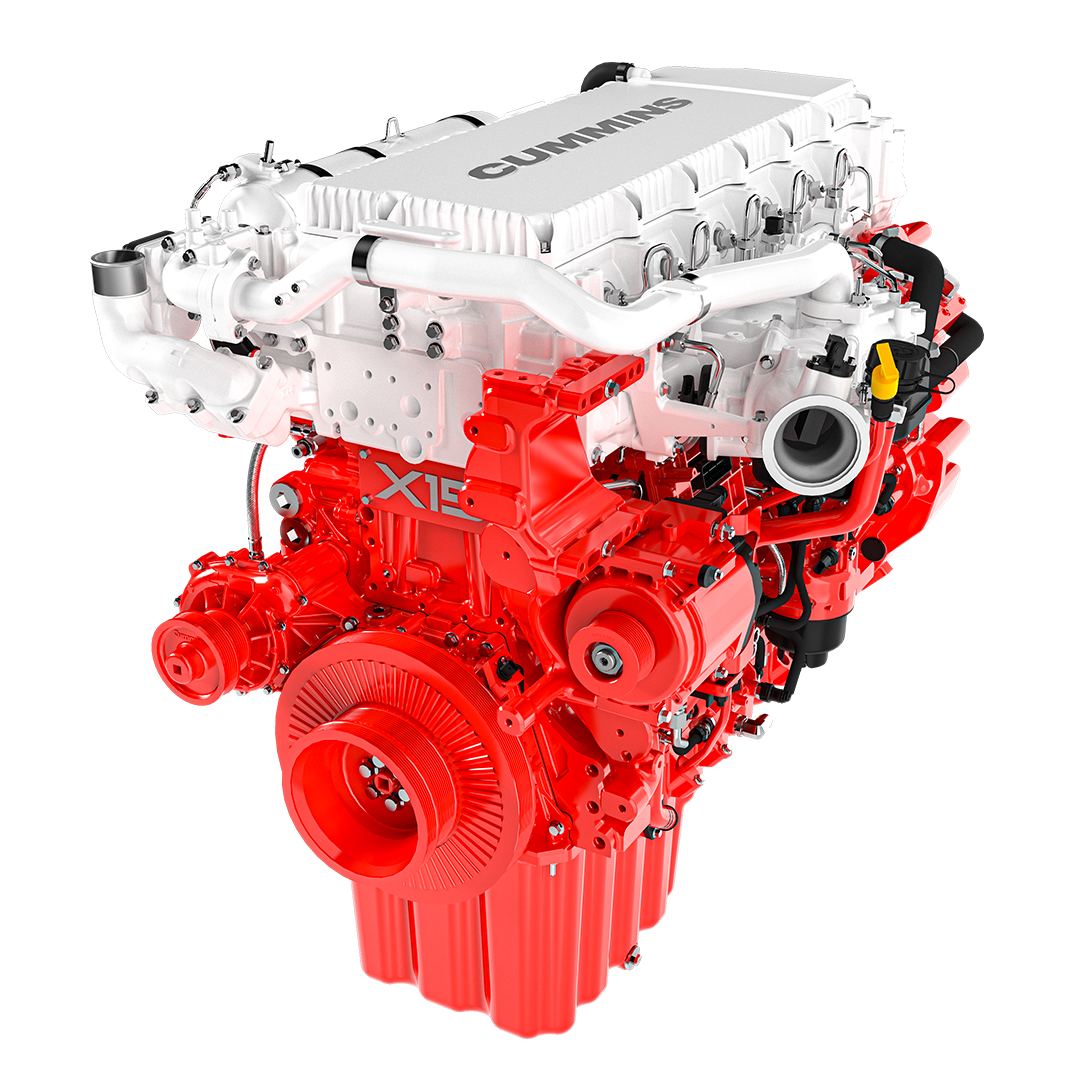

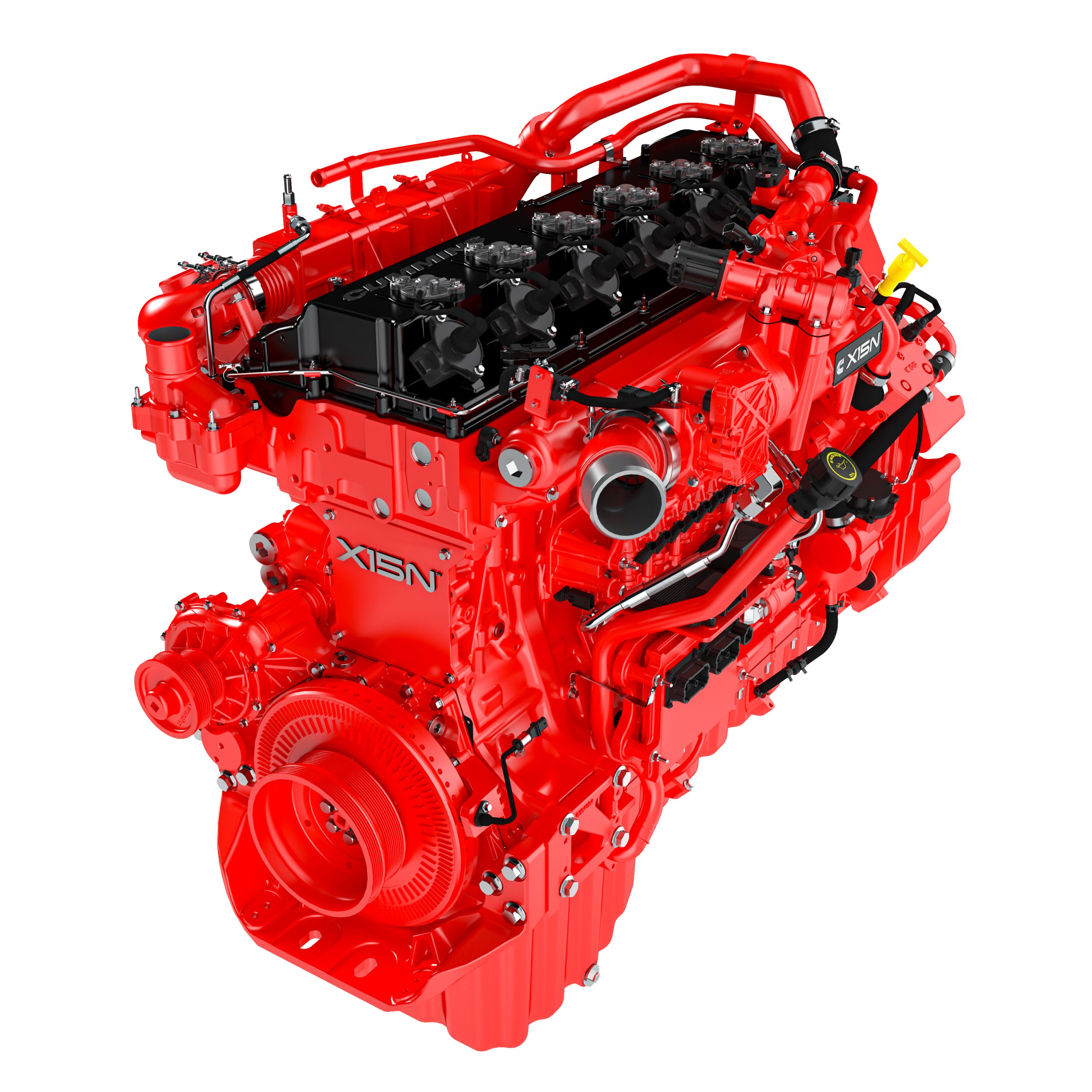

About the Cummins HELM platforms

The engine is built on Cummins’ HELM fuel agnostic 15-liter engine platform. These new fuel agnostic engine platforms feature a series of engine versions that are derived from a common base engine, which means they have some parts commonality. Below the head gasket of each engine will largely have similar components and above the head gasket will have different components for different fuel types. Each engine version will operate using a different, single fuel. The X15N, the natural gas variant, is the first engine on the Cummins HELM platforms available to customers. The Cummins HELM platforms include the B, X10, and X15 engine platforms.

Low Carbon Diesel Fuels

Aligned with Cummins diesel engine portfolio, the new X15 is capable of using biodiesel blends up to 20% and renewable diesel blends up to 100%. Cummins was an early adopter of renewable fuels and continues to advance use of higher biodiesel blends and renewable diesel. These low carbon diesel fuels have been proven to reduce carbon intensity of diesel fuel consumption and are readily available in today’s fueling infrastructure.

Cummins Digital Capability

Cummins’ commitment to internal combustion engine innovation is complemented by its commitment to offering digital products and services that enhance the entire life of every Cummins engine. This includes securely connecting real-time data from vehicles on the road to maintenance and service operations, giving customers an unparalleled ability to look ahead, streamline operations and minimize downtime.

Cummins customers can expect a digitally enriched experience over the life of their vehicles, including newly released features that connect in-mission operations directly to maintenance and repair processes for more seamless end-to-end fleet management.

The new X15 is equipped with Acumen, which provides digital connectivity and direct, immediate access to a range of applications and capabilities. These capabilities provide value throughout the lifecycle of the engine and include over-the-air calibration, predictive service recommendations and additional features that help fleets keep their trucks and equipment on the road.

Source: Cummins

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.