Continental has developed a new air spring monitoring system that provides air pressure, temperature, and positioning data using a fraction of the components required by conventional air spring height measurement methods. The Continental Smart Sensor Air Spring will enable operators in the construction and mining sectors to gain efficiency and reduce costs, while achieving better monitoring of their equipment in mobile and stationary applications.

A smarter solution to a critical need

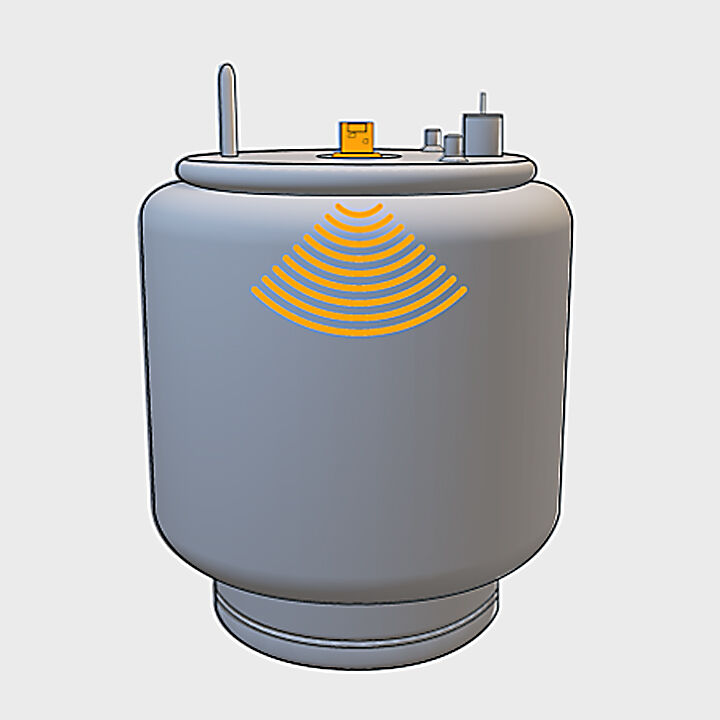

Monitoring air spring pressure, temperature, and height is critical to safe and efficient operations for many air spring applications. Traditional air spring monitoring technologies can require complex installation and calibration methods, which can create logistics and maintenance challenges in the field. By integrating an ultrasonic sensor inside the air spring, the Smart Sensor Air Spring reduces the number of components required for monitoring from more than ten to only one. Using a contactless and wear-free sensor and plug & play installation, the Smart Sensor Air Spring also provides a reduction wiring harness handling requirements over traditional analog air spring monitoring.

The Continental Smart Sensor Air Spring’s digital monitoring makes it less costly to implement, more reliable to operate, and easier to maintain in the demanding environments of mining and construction. Logistical challenges are minimized, operational processes at manufacturing plants are streamlined, and the need for calibration is eliminated.

Continuous monitoring and automatic adjustments

With the Continental Smart Sensor Air Spring, data is continuously transmitted to an electronic control unit. Based on the data, the height of the equipment is automatically and electronically adjusted to the respective target values. This electronic monitoring process prevents air springs from unnecessary energy losses while improving their efficiency and safety.

Built for real-world conditions

Construction and mining machines and equipment must deliver peak performance day in, and day out, in demanding environments of dust, mud, and dirt as well as weather extremes. The compact and robust product design of the Smart Sensor Air Spring protects the sensor by placing it inside the spring, protecting it from dirt, ice, fluids, or mechanical impact. The simplification enabled by digital monitoring makes the air spring safer, simpler, and more efficient for customers.

Simple implementation, advanced monitoring functions

The Continental Smart Sensor Air Spring requires only two cables; one to connect the air spring control system and the other for the data connection. The air spring’s status is monitored automatically, and the data is transmitted to the machine controller providing reliable, real-time monitoring of the equipment’s status.

Through the integrated plug-and-play measurement system, the Continental Smart Sensor provides one source for data analytics and autonomous vehicle control. Having detailed, real-time data not only enables superior monitoring, but also provides a data set that can be used to guide proactive maintenance. Operators can detect irregularities early on and alert the driver in the event of overload or malfunctions to avoid unnecessary parts replacements and reduce downtimes.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.