At the joint John Deere and Wirtgen Group booth at the show, Wirtgen will be presenting a cross section of its extensive portfolio of premium products for cold milling, recycling, soil stabilization, and concrete paving. Alongside nine exhibits from three different product sectors, this year’s presentation will also focus on digital system solutions and assistance systems.

Cold Milling Machines for Construction Sites of All Sizes

Wirtgen will be showing its high-performance, half-meter cold milling machine with rear loading, the W 50 Ri. This machine features a simple operating concept and a range of automated functions. Another highlight at the show is the front loader W 120 Fi for working widths of up to 4 ft 3 in (1.3 m). The John Deere engine of this F-Series compact milling machine has been specially adapted to meet the particular requirements of cold milling applications. The versatility of the company’s portfolio of cold milling machines is also underscored by the two F-Series large milling machines being exhibited at the show. The W 210 Fi is the ideal solution for a broad spectrum of applications, ranging from surface layer rehabilitation and complete pavement removal to fine milling work. In the development of the W 250 Fi, Wirtgen’s most powerful large milling machine, the focus fell on the optimization of milling performance and material loading capacity to ensure maximum productivity.

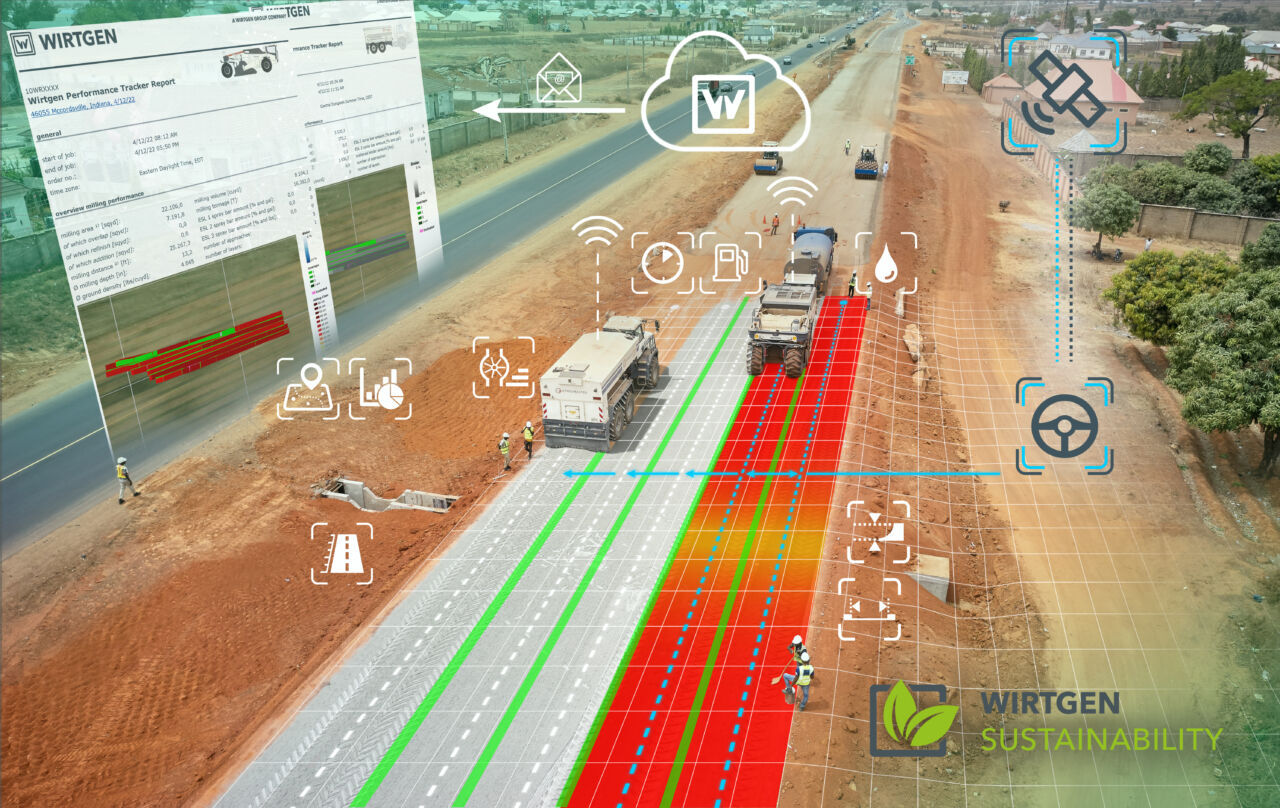

F-Series cold milling machines are available with the innovative Mill Assist machine control system and Wirtgen Performance Tracker (WPT), which enables precise and reliable digital documentation of the work performed on the construction site.

Cold Recycling and Soil Stabilization – Sustainable and Cost-Efficient

The responsible handling of valuable resources was a key consideration in the development of the W 380 CRi, the WR 200 XLi, and the WR 250i. As a rear loader with a mixing capacity of up to 800 t/h, the W 380 CRi is the ideal choice when it comes to the rehabilitation of wider roadways and can be used for both cold in-place recycling (CIR) and full-depth reclamation (FDR) projects. The WR-series recyclers with all-wheel drive are used for both cold recycling and soil stabilization operations. With a working width of 7 ft 10 in (2.4 m) and high milling and mixing performances, they are also ideal for use on challenging projects with high daily productivity requirements. Their digital system solutions – the AutoTrac steering system and the WPT (Wirtgen Performance Tracker) documentation system – further increase process efficiency.

Flexibility During Inset and Offset Concrete Paving

Wirtgen will be showing two extremely adaptable machines for concrete paving, the SP 15i and the SP 94i. The SP 15i enables flexible positioning of the slipform paving mold, which is an enormous advantage when producing monolithic profiles in the offset process. The machine also features an extendable operator’s platform that provides a better overview of the working area and the paving results. The machine can also be remotely controlled with the specially developed AutoPilot 2.0 control system. The SP 94i is a fully modular inset slipform paver in the 30 ft class (10 m). The 4-track paver with the TeleMold system, which enables fast and flexible variation of the paving width by up to 3 ft on each side – i.e., a total of 6 ft – will be exhibited at the show in Las Vegas.

Innovative Cold Milling Technologies

The Mill Assist machine control system increases process efficiency during cold milling applications. In automatic mode, the system strikes the most favorable balance between performance and operating costs. The power management system automatically adjusts the engine speed and the milling drum speed to deliver the actual power required for each situation. The lower speed range enables a significant reduction of fuel consumption and pick wear. The upper speed range enables the achievement of an optimal milling pattern, even in the case of higher area performance rates. The operator can also preselect one of three working strategies: “ECO,” “performance-optimized,” or “milling pattern quality.”

Wirtgen Performance Tracker (WPT) enables precise and reliable documentation of the milling performance. WPT uses a laser scanner to determine the cross-sectional profile to be milled. The surface milling performance and milling volume are then precisely determined using GPS positioning and other sensors. The most important information is displayed on the machine’s control panel. An automatically generated report can be sent to the machine’s owner by e-mail. This reduces the time, effort, and costs required for the completion of the project.

Cold milling expert Tom Chastain from Wirtgen America will be providing more detailed insights into established milling and profiling practices and technologies in the course of the Conexpo Education Sessions on March 16, 2023, in West Hall 208 – 210 in the Las Vegas Convention Center.

Resource-Friendly Technologies for Recycling and Soil Stabilization

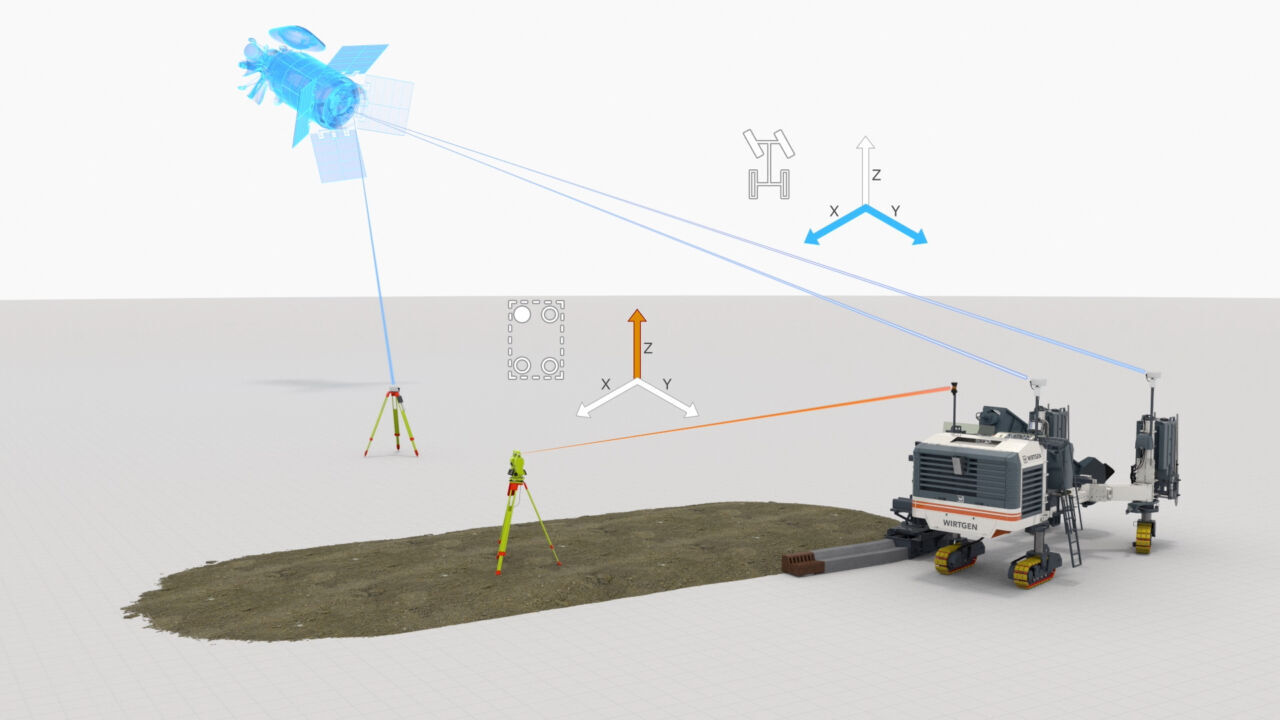

The satellite-based AutoTrac steering system for Wirtgen WR-series recyclers enables precise and efficient completion of each successive project task. It steers the machine with a precision measured in centimeters on the basis of a previously determined reference strip and a specified overlap of adjacent strips and enables consistent utilization of the machine’s ideal working width. This results in greater process efficiency and the minimization of environmental impact.

The WR-series machines are also available with the Wirtgen Performance Tracker. The system registers all relevant location-specific working parameters to provide a comprehensive database for construction site analysis and documentation. In the case of soil stabilizers, these include the working width and depth, the area and distance worked, the fuel consumption, and numerous other parameters.

Stringless Control for Greater Efficiency and Safety

Developed by Wirtgen, the AutoPilot 2.0 is a control system for stringless paving that provides an alternative to the conventional method of mechanically scanning a stringline. The system, which precisely controls both the machine’s height and steering, is available for all offset pavers and placer/spreaders. A GNSS signal and, depending on the configuration, various local sensors – e.g., an ultrasonic sensor on the machine – serve as a reference. The need for a stringline is eliminated and the time and effort otherwise required for setting one up and removing it is no longer required. It also enables fast and precise paving of tight radii and complex geometries. The Wirtgen AutoPilot 2.0 system provides machine control and remote control from a single source.

Source: Wirtgen Group

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.