Two new Cat mulchers for tracked and wheeled excavators and forest machines deliver reliable operation in tough forestry applications.

With their easy-to-maintain design, these mulchers incorporate a number of safety features to protect both workers and equipment at the jobsite.

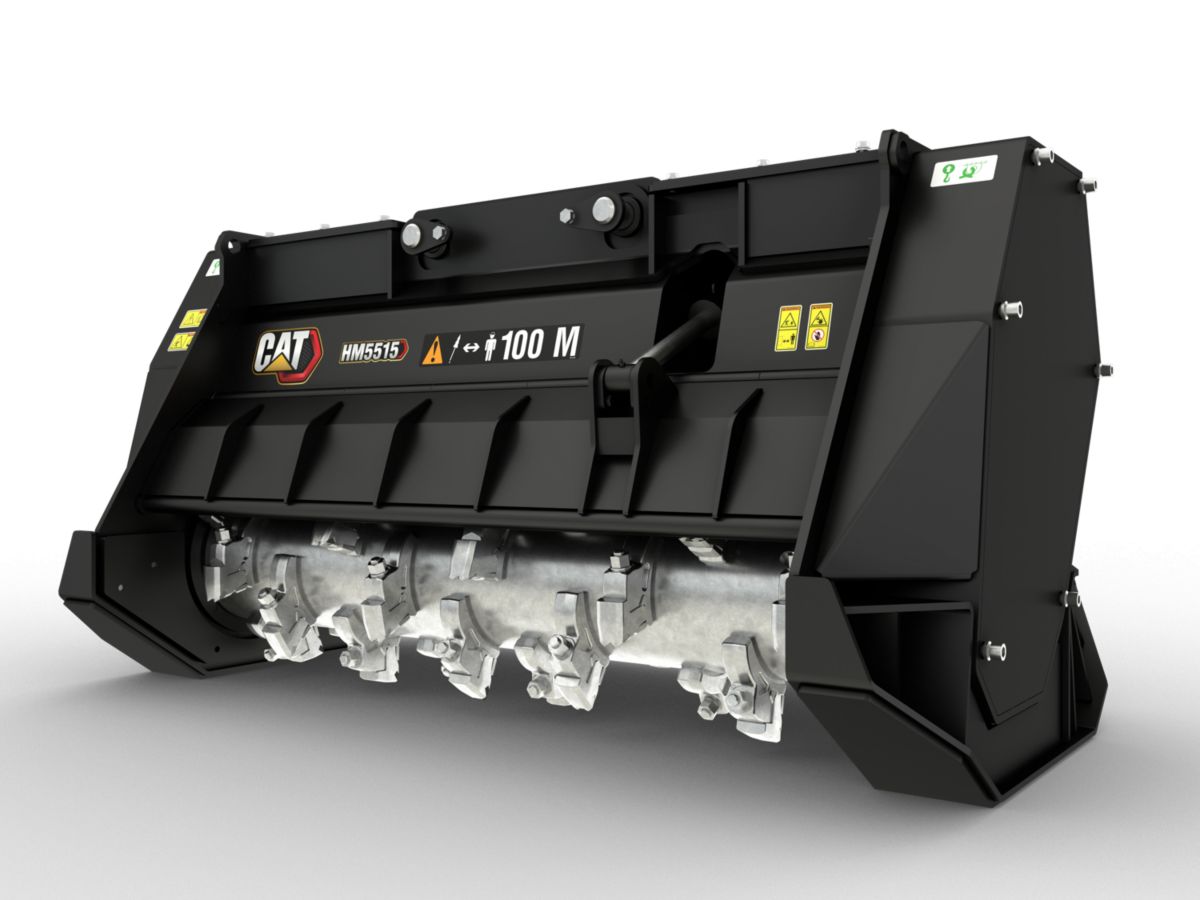

With the addition of the new Cat HM3013 and HM5515 models, Caterpillar now offers a mulcher attachment for Cat front-reach machines from 11 to 36 tons (10 to 32.7 tonnes) and long-reach front machines from 40 to 52 tons (36.3 to 47.2 tonnes).

The HM3013 has a new dedicated bite limiter drum, while the HM5515 offers a standard drum. Featuring an aggressive edge of the blade with the limiter and counter knives, the dedicated bite limiter of the HM3013 produces an exceptionally fine final product. The bite limiter drum design excels in mulching applications where rocks are minimal with large amounts of standing timber.

Key components on the mulchers factor into their consistent, reliable performance. The variable torque hydraulic piston motor shifts between high speed, low torque and low speed, high torque to deliver speed when it’s needed and power when it counts. Hardened counter blades mounted inside the housing help break down the finished material, which can increase the rate of composting.

Maintaining these new mulchers is fast and simple. Multiple service panels on each model provide easy access for quick adjustments. Further simplifying maintenance and reducing downtime, internal components can be easily removed in the field through the access panels. The poly chain belt drive transmission eliminates slippage on startup, increasing reliability and reducing maintenance costs. Most of the wear parts are made to be field-replaceable to keep the HM3013 and HM5515 working at peak efficiency.

The ability to adjust the hydraulic mulching door allows the operator to control the material throw, increasing operating safety, especially critical on roadside clearing applications or when working near powerlines. Ground-level primary grease points increases daily maintenance safety. Bolt-on, replaceable skids keep the mulcher from digging into the ground or into materials that can increase wear or cause damage.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.