Kalmar, part of Cargotec, has entered into an agreement with Companhia Siderúrgica Nacional (CSN) for the supply of nine Kalmar Rubber-Tyred Gantry Cranes (RTGs). The cranes will be delivered to Sepetiba Tecon terminal in Rio de Janeiro, Brazil.

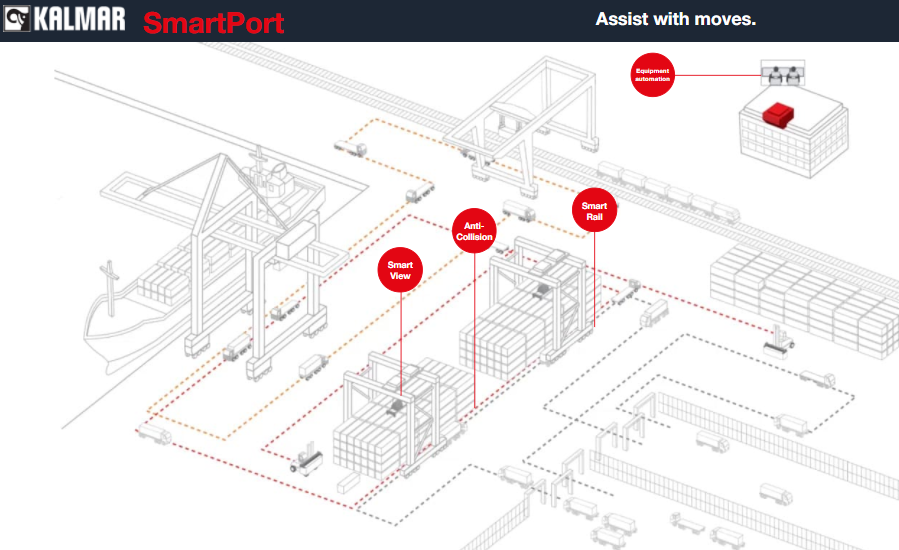

The order that includes Kalmar SmartPort operator assistance features was booked in Cargotec’s Q4 order intake. Delivery is scheduled to be completed in Q1 2022.

One of Brazil’s main container terminals, Sepetiba Tecon S.A. is located in the Port of Itaguaí, some 80 kilometres from the city of Rio Janeiro. Inaugurated in 1998, the terminal offers its customers rail and sea connections at the convergence point of Brazil’s main highways, close to the country’s main economic and industrial centers.

The Kalmar RTG combines the best of diesel and electric technology for fuel savings, low emissions and easy maintenance. The units delivered to Sepetiba Tecon will be configured to handle 6+1 wide with 1-over-6 high stacking and will have a lifting capacity of 40 tonnes under the spreader. To ensure greater fuel economy and lower emissions, the cranes will include a Variable Speed Generator system, which automatically optimises the RPMs according to the required power, fully-electric Bromma spreaders and large tyres that enable minimal ground pressure.

The RTGs will be fitted with Kalmar SmartRail automated gantry steering system that automatically controls the gantry within centimeter grade accuracy on the travelling path, improving the terminal’s operational efficiency. The cranes will also be equipped with SmartRail CPI (Container Position Indication) system, a real-time tool to track and report container moves.

Troy Thompson, Vice President, Sales, Kalmar Americas:

We are delighted that Sepetiba Tecon chose us to support their ambitious expansion plans, and we are looking forward to establishing a long-term partnership with them. Our proven and reliable equipment, combined with the service capabilities we offer, help customers improve their operational performance as they develop their operations to meet the demands of the future.

Source: Kalmar

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.