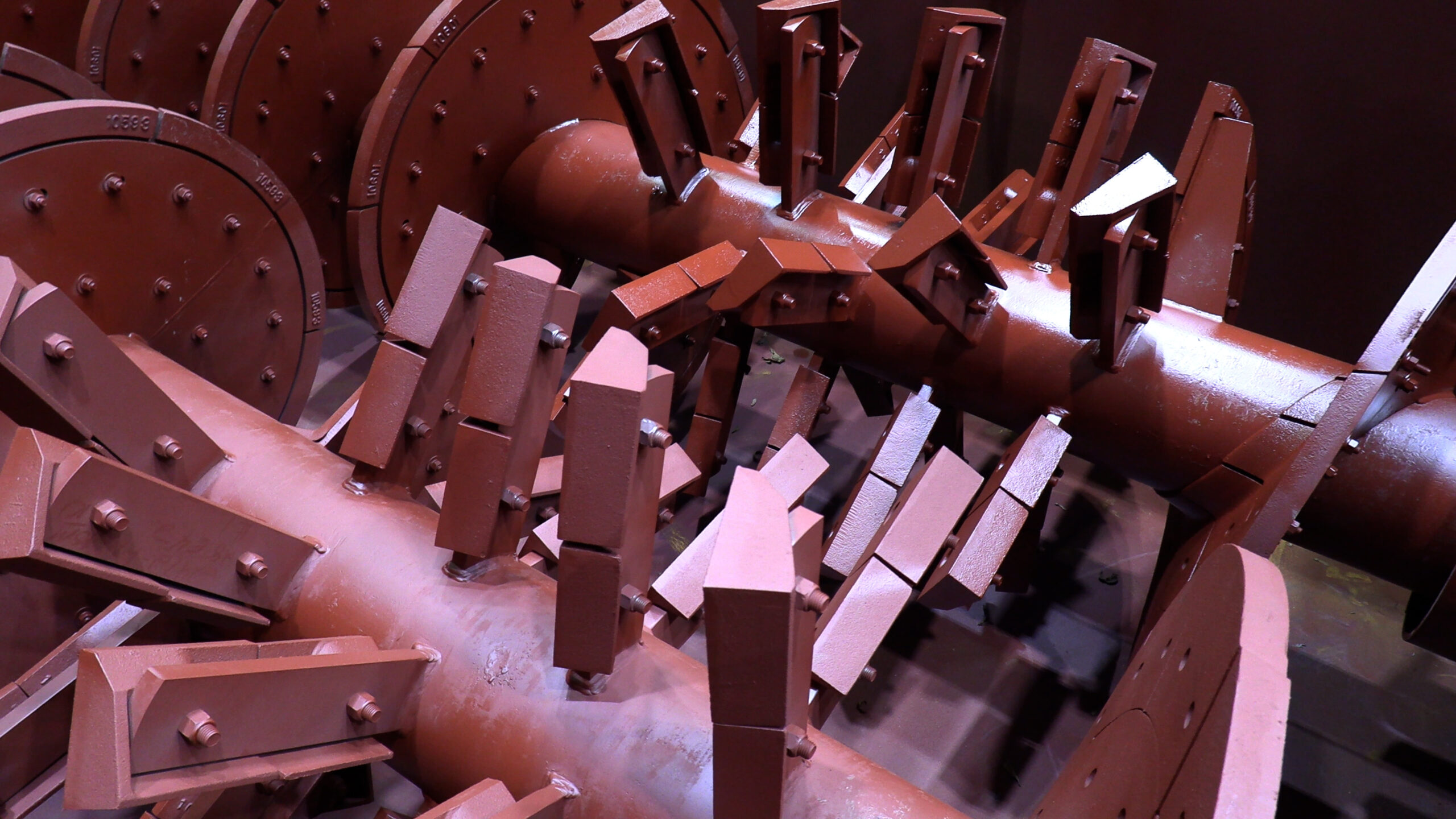

McLanahan Coarse Material Screw Washers feature more paddles than any other on the market. This provides increased attrition and retention time for a cleaner product.

Added retention time provides a cleaner product, therefore a more valuable product coming off the end,

said Regional Sales Manager Stephen Shortsleeve.

More Paddles, Cleaner Product

McLanahan designs its Coarse Material Screw Washers with 20 paddles in the scrubbing area, about 2-4’ from the back plate. Competing units only have 12-15 paddles. The additional paddles provide increased scrubbing to remove deleterious material from the feed before it is conveyed by the spiral screw flights on the remainder of the shaft to discharge as a clean product.

Ideal for removing light, loamy clay, as well as crusher dust, dirt and light vegetation, from an aggregate feed, McLanahan Coarse Material Screw Washers are available with this combination of paddles and screw flights or with paddles running the full length of the shaft for even more scrubbing action.

Either option provides a good washing and is dependent on the application, which we review,

said Shortsleeve. “We test samples from the site in our in-house laboratory to determine the best paddle configuration for optimum scrubbing.”

Reversible Paddles, Longer Retention Time

To further increase retention time, the paddles on McLanahan Coarse Material Screw Washers can be reversed. Reversing the paddles keeps the material in the scrubbing area longer. This gives producers the flexibility to meet changing feed conditions should they choose to move the unit or feed it larger amounts of deleterious material.

Longer Wear Life

McLanahan Coarse Material Screw Washer paddles are fabricated with abrasion-resistant white iron for long wear life. When paddles eventually reach the end of their usable life, replacing them is easy with McLanahan’s two-piece paddle design.

Simplified maintenance and innovative solutions are two of the many advantages of working with McLanahan.

“We understand the urgency that customers have”, Shortsleeve said.

“We understand how downtime is going to affect the end user, so we make sure it’s done right, it’s designed right and it’s provided in a timely manner.”

Source: McLanahan

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.