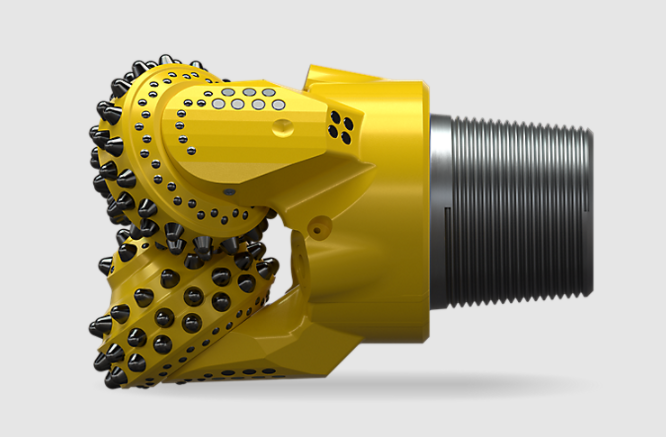

Epiroc is now launching Omega S – the new tricone rotary drilling bit.

A single sealed bearing bit that, when the seal eventually wears off, transforms to an air bearing bit thus increasing drilling performance with up to 30 percent compared to a standard air bearing bit.

State of the art engineering

The secret behind the new single sealed bit is simply innovative engineering. The Omega S begins as a single-sealed bearing bit. After the seal has worn off, the bit automatically transforms into an air-bearing bit – adding 30 percent extra lifetime.

With the Omega S our customers now get considerably lower cost per meter drilled. The transformation from a single sealed bit to an air bearing bit is seamless and requires no down time for the operator. It is simply a more efficient drill bit.

says Bahadir Ergener, Product Line Manager (PLM) Rotary at Epiroc.

Each cone is equipped with a durable hydrogenated nitrile butadiene rubber (HNBR) seal, which enables vacuum lubrication of the bearings. Once the seal has been worn out, and vacuum is lost, cooling air begins to flow over the bearings. This automatically transforms Omega into an air-bearing bit – adding extra lifetime.

Sustainability and safety – a competitive advantage

Extensive testing carried out around the world has proved that the Omega S provides about 30 percent increase in drilling distance compared to standard air bearing bits. This means higher productivity but also that there will be fewer bits manufactured in total over time, which reduces the consumption of raw material, the transportations and the ecological footprint. More meters drilled per bit also means increased safety through reduced operator interaction with the drill bit.

Sustainability and safety are important factors for us when developing new products and we believe this will also provide our customers with an advantage towards their competitors when competing for new contracts.

Bahadir Ergener, Product Line Manager.

Source: Epiroc

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.